Two of the most popular types of sandwich panels with applications in construction and industrial purposes are PU/PIR sandwich panels and pure rock wool sandwich panels. Both are excellent insulators but have different compositions, performances, and applications in a project. In this article, we will discuss their definition, most critical characteristics, and an overview to assist you in making the right decision regarding the proper sandwich panel for your application.

1. What is a PU/PIR Sandwich Panel?

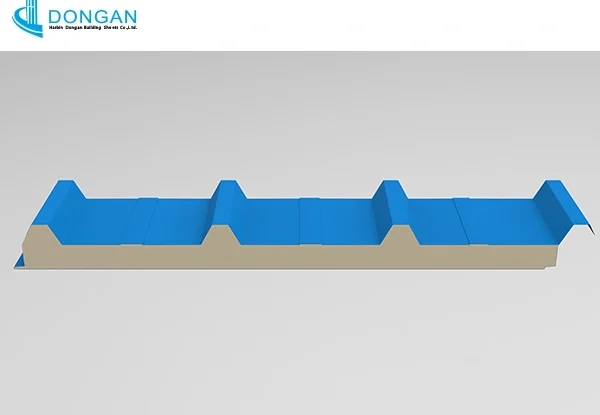

PU/PIR sandwich panel is a construction product consisting of polyurethane (PU) or polyisocyanurate (PIR) foam core being sandwiched in between two metallic or non-metallic facings. The panels find extensive usage in cold stores, warehouses, and industrial establishments due to the enhanced thermal insulation.

Major Attributes of PU/PIR Sandwich Panels:

- High Thermal Insulation – PU/PIR foam is less conductive thermally than the majority of insulant products, thus, the sandwich panels are extremely energy efficient.

- Lightweight & Strong – Lightweight and easy to install but remain structural strength.

- Fire Resistant – PIR foam is more fire resistant than PU, usually rated B1 or B2.

- Moisture Resistance – Closed-cell structure does not absorb moisture, reducing the risk of mold or corrosion.

- Cost-Effective – A bit more expensive to purchase, their ultimate energy efficiency makes them well worth it.

Due to these benefits, PU/PIR sandwich panels are best applied in climate-controlled spaces like food processing facilities and refrigeration systems.

2. What is a Pure Rock Wool Sandwich Panel?

A pure rock wool sandwich panel is a facer sandwich of rock wool (stone wool) insulation core sandwiched between rigid facings like steel or aluminum. Rock wool is a synthetic product of molten basalt rock and slag and is, therefore, naturally fire-resistant. The panels find widespread use in fire-exposed uses, sound-sensitive buildings, and high-temperature industrial processes.

Key Features of Pure Rock Wool Sandwich Panels

- Good Fire Resistance – Rock wool is incombustible and generally of A1 or A2 fire rating and hence finds application in fire-resistant construction.

- Enhanced Sound Insulation – The dense fibrous structure has good sound absorption properties, and such sandwich panels are best suited for application in auditoriums, studios, and hospitals.

- Heat Insulation – Although inferior to PU/PIR, rock wool is also good in heat insulation.

- Water & Corrosion Resistance – Hydrophobic additives can be incorporated for increased water resistance.

- Environment-Friendly – Since rock wool naturally occurs in minerals, it is eco-friendly and recyclable.

Pure rock wool sandwich panels are optimally suited in fire-rated walls, buildings, and HVAC where improved acoustic performance is needed.

3. PU/PIR vs. Pure Rock Wool Sandwich Panels: Comparison

| Feature | PU/PIR Sandwich Panel | Pure Rock Wool Sandwich Panel |

| Thermal Insulation | Excellent (Lower thermal conductivity) | Good (Higher than PU but less efficient) |

| Fire Resistance | B1/B2 (PIR better than PU) | A1/A2 (Non-combustible) |

| Sound Insulation | Moderate | Excellent (Superior noise reduction) |

| Weight | Lightweight | Heavier (Denser material) |

| Moisture Resistance | High (Closed-cell structure) | Moderate (Can be treated for water resistance) |

| Cost | Higher initial cost, but energy-saving benefits | More affordable, but installation may require additional support |

| Best Applications | Cold storage, warehouses, industrial buildings | Fireproof walls, soundproof rooms, high-temperature areas |

4. Conclusion: Which Sandwich Panel Should You Choose

Pure rock wool sandwich panel and PU/PIR sandwich panel both have their advantages depending on project requirements.

- Utilize PU/PIR sandwich panels where high thermal performance, low weight, and water tightness are needed—ideal for refrigeration and energy-saving applications.

- Utilize pure rock wool sandwich panels where fire performance, sound insulation, and heat resistance are critical—ideal for schools, hospitals, and industrial firebreak applications.

Your final sandwich panel is your preference according to your personal need for insulation, security, and cost. Knowing the differences, you can now make an intelligent decision for your industrial or construction building project.

Enjoy the benefits of both PU/PIR and plain rock wool sandwich panels in high-performance building systems and reap the best.